==============================================================

ANIMATION: ( MPEG(768K) )

--------------------------- wave2d_45x180_example.html --------------------------

Instructions for using this form:

Simulation results returned:

Below are images with

back-ground-info that describes this problem in more detail.

TERMS DEFINED

==============================================================

ANIMATION: (

MPEG(768K) )

How to Visually Interpret Results

==============================================================

BULK WAVE PROPAGATION SIMULATION IN UNIDIRECTIONAL Gr/Ep

----------------------------------------------------------------------------------------------------------------

Unlike isotropic materials waves propating in anisortropic materials deviate from

the wave normal ni. This anisotropy quides the wave energy propagation shown in

the animations provided above. From this simulation new relationships can be

seen: 1) the faster moving QL wave has a longer wavelength, 2) diffractions

from reflected bulk waves create Rayleigh surface waves, 3) the reflected QL

wave energy propagates back towards the origin, 4) this refection does not

generate another bifrucation of energy into yet another QL & QT wave. This

information suggests that waves could be launched preferentially.

Because a deformed mesh shows shows the wave types, L, QL, QT, or T,

more clearly, highlighted above as red and

blue regions, the animation

of simulation results are shown as a deformed mesh.

Below is specific information that describes how to use data in the

form shown in the lower frame.

__________________________________________________________________________

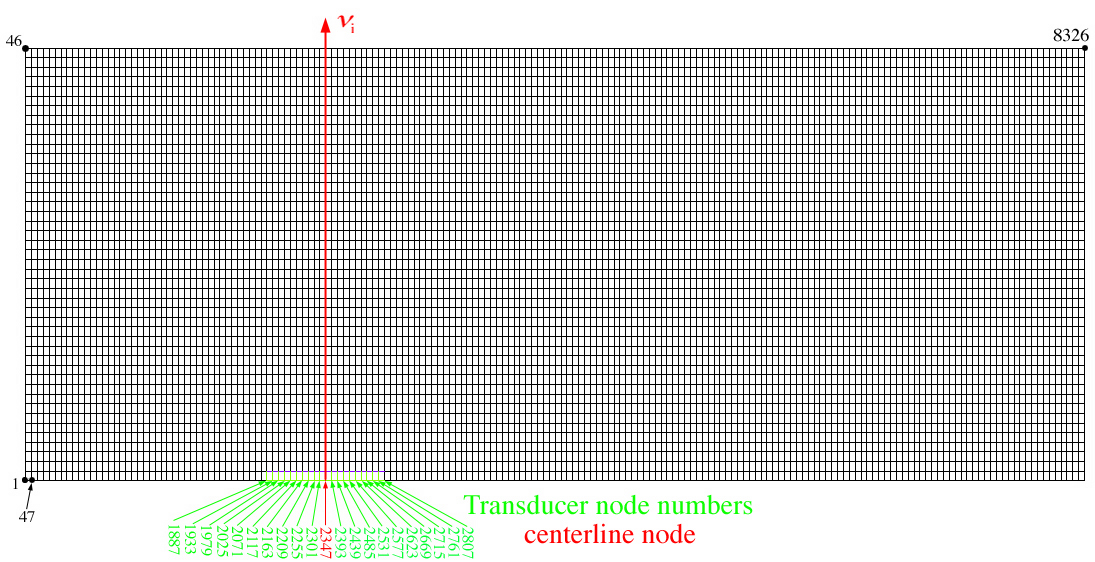

Simulated transducer defined by identifying grid nodes and vibration direction angles:

=========================================================================

View larger format

The FEM mesh size above cannot be changed in this module, however the

number of nodes that define the simulated

transducer (green) can be changed in the form provided in the lower

frame. At the bottom of the form the user can

select which nodes are active by altering the # Nodal Displ.,

e.g. change 21 to 11, in the first line on the form and the

corresponding Number of Elements in One Wavelength

which is one less that the total # Nodal Displ., e.g. change

20 to 10. The FEM program sets the Number of Elements in One

Wavelength equal to the transducer length

highlighted in green. For small transducers, e.g. 4 elements/wave

length, the corresponding L, QL, QT, or T waves

launched by the simulated transducer are equally small which gives rise

to dispersion, i.e. slower wave group velocities.

At 4 elements per wavelength the group velocity goes to zero. Next to

the node numbers defined at the bottom

of the form are the prescribed displacement directions in degrees which

is set at 00.0 degrees. At 00.0 degrees these

nodal displacements are restricted to move in the horizontal direction,

which generates transverse waves. If these

angles are set to 90.0 degrees these nodal displacements are restricted

to move in the vertical direction, which generates

longitidinal waves